According to Business Insider, almost 30% of food delivery drivers have admitted to munching on the food they deliver. While that statistic is horrifying, it’s also enlightening. How accessible is the food that you’re serving to your customers? What are the signs of tampered food in packaging? What if a customer got sick because someone opened and touched their food? How can the food industry prevent theft when tamper protection is missing from store packages? First and foremost – food safety! And yes, theft as well. This is very scary to think about, and we understand. Tamper protection in the food industry is a serious matter.

Here at Inline Plastics, we have been focused on protecting food for over fifty years. In this article, we will be sharing insights into how tamper-evident features protect food products. This exploration covers the evolution of food safety packaging and how modern solutions help retailers, restaurants, and food businesses ensure product security.

The Need for Tamper Evidence

In 1982, authorities discovered that bottles of Tylenol had been tampered with in pharmacies in the Chicago metropolitan area, resulting in disastrous and fatal consequences. Thus, the need for tamper evidence was born. Consumers needed to know that what they intended to use was safe for human consumption, and it hadn’t been opened since leaving the manufacturing facility.

In 1982, authorities discovered that bottles of Tylenol had been tampered with in pharmacies in the Chicago metropolitan area, resulting in disastrous and fatal consequences. Thus, the need for tamper evidence was born. Consumers needed to know that what they intended to use was safe for human consumption, and it hadn’t been opened since leaving the manufacturing facility.

Johnson & Johnson, quick to handle the crisis, developed induction seals on all its medicines. These small, metallic seals proved to the consumer the package was not tampered with. Other industries soon followed, and seals quickly became the norm.

This was certainly a shock to the pharmaceutical industry. It also revealed how vulnerable other sectors were to tampering. In the post-pandemic era, consumers are more aware of the need for safety and protection. A key industry that is certainly of concern to consumers is food safety.

What Does Tamper Evidence Look Like in Food Packaging?

Let’s first divide tamper protection into two categories: tamper-evidence and tamper-resistance

- Tamper-resistant mechanisms make the package incredibly difficult to open.

- Tamper-evident mechanisms show the consumer that the product was opened by someone else than themselves.

Level One

Imagine a scale of tamper protection. At the most basic level, the easiest way to let your customers know their food wasn’t opened was to place an easy-to-open package inside a bag and staple it shut. This more commonly applies to restaurants, not so much retail stores. Could someone just remove the staple, cough into their hand, grab a dumpling, and staple it back shut? Now, we are not here to accuse all delivery drivers of being unsanitary beings putting their fingers in your spaghetti. We’re here to talk about safety.

Level Two

The next level of tamper protection is placing a sticker or label over the food package. We see this tamper protection method used frequently in grocery stores, but restaurants may also apply labels to packages to ensure safety. Can someone easily peel off a takeout container’s label, open the undamaged package, take what they want, close it again, and reattach the label? That is not impossible, but probably not very common. Ripping that label to get to that food is not unbearable, but it often remains a little piece sticking on the package.

Level Three

Shrink bands offer a bit more protection. Shrink bands were proposed as the food packaging industry got closer to creating a more proper tamper-resistant food packaging while maintaining the clarity of the product. These are the tight plastic seals around the perimeter of the food packaging. If you remove the band, nobody would know it was even there in the first place. These bands were, therefore, only tamper-resistant, not tamper-evident.

They have an additional disadvantage: they must be heated for the bands to shrink around the package. That means no matter what food went into the package, from cut pineapple to egg salad, the final product had to be run through a heating tunnel. It’s not hard to imagine how this heating process could affect the quality of the food. Not to mention playing “safety roulette” once consumers’ scissors pierce the package—because these bands seem designed to be impossible to open without tools.

A New Era of Tamper Protection

Over the last twenty years, significant investment has been made in tamper protection. Manufacturers have engineered packaging that integrates tamper resistance and/or tamper evidence and is intuitive enough to let people know that their food is safe. These technologies come in different shapes and sizes.

Advantages of New Tamper Protection Technologies

The advantages of these new technologies can be summed up in three simple words: food product safety. Tamper protection elements clearly show customers the product wasn’t opened in any way, gaining trust and assurance in your business.

Think of two pizza shops side by side. One offers simple packaging for their food—placing slices in a paper box. How do the customers know that a delivery driver or hungry cook hasn’t had their fingers in the mozzarella sticks? The other shop offers tamper-evident packaging or delivers the food in a tamper-evident bag. Every one of those mozzy-sticks are still there. Which business do you think has a greater chance of success? It’s the one who invested in their customers’ health and safety.

Can There Be Any Disadvantages?

There are a few practical disadvantages. If a food service professional, such as a restaurant owner, needs to open a package to change or add something to the product inside (think of forgetting to add sauce over pasta), they will have to:

- Open the package.

- Remove the contents and place them in a new package.

- Add or make whatever changes to the food.

- Seal the new package.

And that is time-consuming and costly! Here’s a fun example from retail: cakes! Bakers prepare these delicious treats offsite and deliver them to the store. This is where they undergo a magical transformation. Picture this—a plain cake turns into a dazzling Disney princess masterpiece for Phoebie’s 4th birthday. But here’s the catch: if the cake arrives in tamper-evident packaging, the store has to unwrap it, decorate it, and then repackage it all over again. Talk about a royal hassle!

Foods that consumers package themselves, such as items from salad bars, self-service stations, or leftovers in restaurant doggie bags, are good examples of situations where tamper-evident or tamper-resistant packaging is generally unnecessary.

So, while these packages offer great benefits, there are situations where they simply aren’t necessary.

And let’s not forget about the cost. With all these sophisticated features, you may end up paying a little extra for the added peace of mind they provide. But, like everything else, this depends on the situation.

The Clear Picture: Knowing Your Food Is Safe

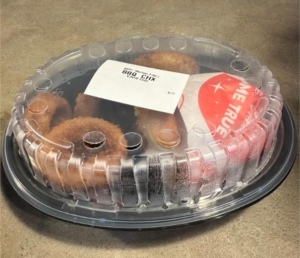

Nobody wants to think of someone sampling the food a customer receives. It’s unsafe, incredibly distressing, and can be very costly. Tamper protection is the most effective way to know that food is safe for consumption. Among the various types of tamper protection, the most effective are foods packed in containers that include both tamper evidence and tamper resistance. The customer can see that their food arrived safely and that you care.

Nobody wants to think of someone sampling the food a customer receives. It’s unsafe, incredibly distressing, and can be very costly. Tamper protection is the most effective way to know that food is safe for consumption. Among the various types of tamper protection, the most effective are foods packed in containers that include both tamper evidence and tamper resistance. The customer can see that their food arrived safely and that you care.

We believe in finding the right fit, not just any fit. Reach out for honest guidance without pressure. Inline Plastics is here to answer your questions.